In the field of modern energy transmission and communication, reliability and safety are non-negotiable. From mountain ridges to coastal regions, overhead lines are constantly exposed to wind, rain, salt, and temperature changes. To ensure stable performance under these demanding conditions, preformed armor rods have become an essential component in today’s power fittings and transmission line systems.

What Are Preformed Armor Rods?

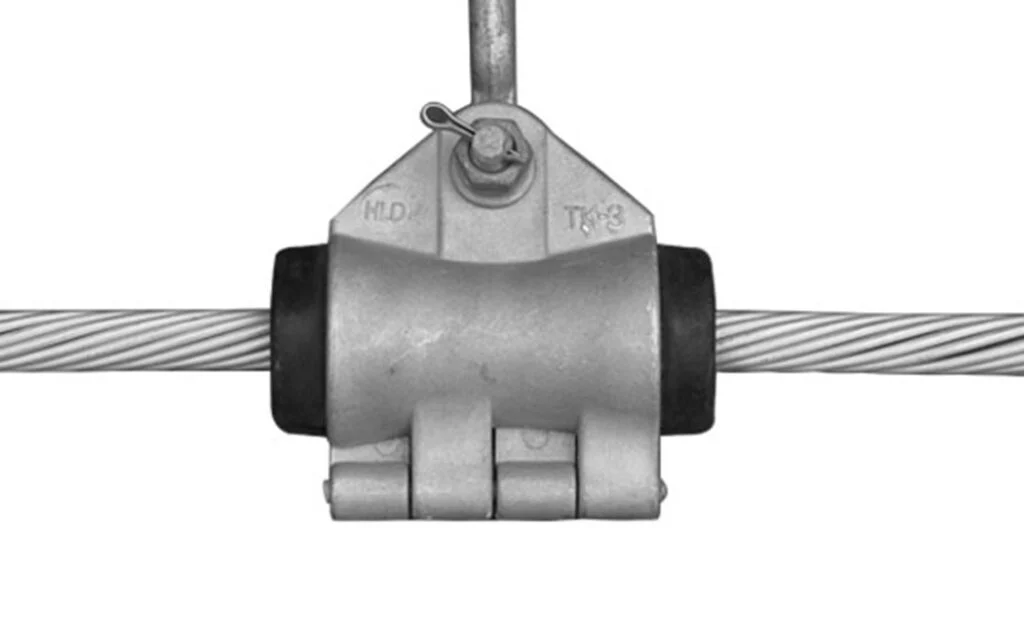

Preformed armor rods—also known as preformed line accessories or conductor protection rods—are helically shaped metal wires designed to wrap around conductors, optical ground wires (OPGW), or ADSS cables.

Each rod is preformed with precise helical geometry, allowing it to fit tightly and evenly around the conductor surface without causing stress concentration.

They serve multiple functions:

- Mechanical protection: Prevents abrasion and fatigue damage caused by vibration

- Electrical stability: Maintains consistent conductivity at joints and connections

- Corrosion resistance: With materials such as aluminum-clad steel or galvanized steel, they resist moisture, salt, and oxidation in outdoor environments

Strength and Durability in Harsh Environments

What makes preformed armor rods exceptional is their ability to perform in extreme weather and high-tension applications.

Thanks to their high-strength alloy structure and anti-corrosion coating, they can withstand:

- Strong wind zones

- Coastal salt fog areas

- Ice and snow loading regions

By distributing mechanical stress along the entire contact area, armor rods prevent local damage and effectively extend the service life of conductors and fittings.

Applications Across Power and Communication Networks

Preformed rods are widely used in:

- Transmission lines (high-voltage overhead conductors)

- Communication cables (ADSS, OPGW)

- Electrical line protection systems (joint reinforcement, vibration control, and conductor repair)

In every installation, their presence ensures a safer, more stable, and longer-lasting connection—keeping power and data transmission smooth and uninterrupted.

Precision Manufacturing with Xingang Machinery

Behind every reliable preformed line product is advanced manufacturing technology.

At Xingang Machinery, we specialize in preformed wire forming equipment—the machines that shape each armor rod with high precision and efficiency.

Our automated forming systems feature:

- Touch-screen pressure control

- High-speed forming up to one cycle per second

- ±1° bending precision

- Compatibility with multiple wire types and diameters

These technologies allow manufacturers worldwide—from India and Southeast Asia to North America and Russia—to produce consistent, high-quality preformed line accessories that meet international power transmission standards.

Conclusion

Preformed armor rods stand as silent guardians of every overhead transmission line, combining strength, flexibility, and precision to safeguard modern infrastructure.

With the right equipment and expertise, they transform from simple metal wires into vital components that ensure every volt and bit of data reaches its destination safely.

At Xingang Machinery, we are committed to supporting global manufacturers with cutting-edge preformed line production solutions—helping build a safer, more connected world.