Precision. Automation. Global Trust.

For over two decades, Nantong Xingang Machinery Co., Ltd. has been a trusted manufacturer of preformed wire and Armor Rod equipment serving power transmission, communication, and rail industries worldwide.

- Auxiliary Machines: Round Head Machines, Belt Sanders, and more

- Automatic Forming Production Lines for Preformed Armor Rods

- Twisted Wire Folding Labeling Systems

- Pre-Twisted Wire Stranding Machines

20+

Years Experience

30+

Countries Served

99.5%

Uptime Rate

500+

Projects Completed

Featured Products

Advanced automation solutions engineered for precision, durability, and multi-material processing

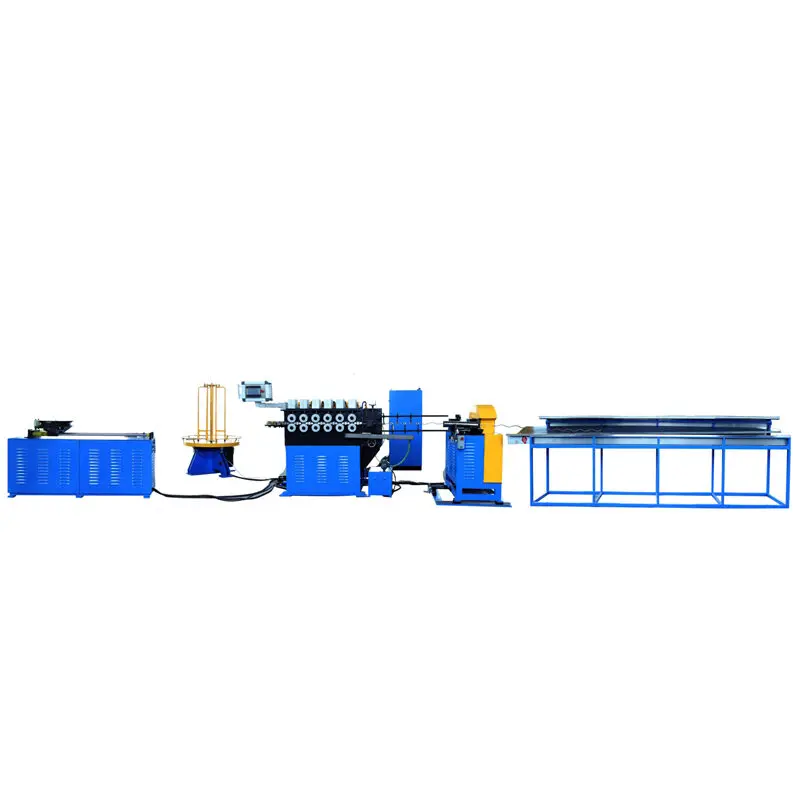

Preformed Armor Rods Automatic Forming Production Line

High-precision preformed armor rod production with ±2mm accuracy and DL/T 763-2001 compliance

+2mm Precision

DL/T 763-2001 Compliant

Multi-material Support

Double-Head Helical Stranding Machine

Dual-head synchronization with programmable angle control and 24/7 operation capability

Dual-head Sync

±1° Angle Control

24/7 Operation

Automatic Preformed Strand Stranding Machine

High-speed stranding with remote monitoring and adaptability to various wire types

High-speed Processing

Remote Monitoring

Industry Applications

Serving critical infrastructure projects across power transmission, communications, and transportation

Power Transmission

Tension clamps, suspension clamps, and conductor protection systems

Communication Infrastructure

Grid construction and telecommunications line equipment

Rail Transit

Special engineering applications for long-span conductor systems

About Us

Nantong Xingang Machinery Co., Ltd

At Nantong Xingang Machinery, we believe in crafting advanced manufacturing solutions. With a legacy that spans decades, our mission has always been to pioneer efficiency and innovation in the industry. Our dedicated team works tirelessly to develop machinery that meets the evolving needs of modern businesses while upholding safety and quality.

From our humble beginnings to becoming a trusted name in smart manufacturing, we are committed to excellence and integrity in everything we do.

Why Choose XINGANG

Your Trusted Partner

Intelligent Control Systems

Features Siemens SMART PLCs and HMI touchscreens for seamless automation and precise control.

End-to-End Solutions

Comprehensive support covering equipment supply, line design, debugging, and technical training to accelerate project deployment.

Global Compliance

Meets stringent international standards and requirements for cross-border projects worldwide.

Proven Reliability

High uptime (>99.5%), robust IP54-rated components, and seamless integration into existing workflows.

Our Solutions & factory audit

In today’s highly competitive industrial field, companies need a trusted partner to provide high-quality and reliable machinery and services. Xingang Machinery is such a company dedicated to providing customers with comprehensive mechanical solutions.

Experienced Team

Innovative Technology

High-quality Products

Customized Solutions

Our production process

From raw materials to complete machine delivery, Nantong Xingang Machinery ensures superior performance through rigorous process control and uncompromising quality standards.

Raw Material Procurement

High-Standard Materials, Quality from the Source

We rigorously select qualified suppliers, ensuring all steel and key components meet international quality standards, laying a solid foundation for high-performance equipment.

1

Rough Processing

The First Gate to Precision

Using advanced CNC lathes, milling machines and other equipment for preliminary processing, ensuring dimensional accuracy and structural stability, preparing for subsequent precision machining.

2

Heat Treatment & Tempering

Scientific Heat Treatment, Strengthening Core Performance

Through high-temperature heat treatment and tempering processes, significantly improving component hardness, wear resistance and structural stability, ensuring long-term efficient operation.

3

Precision Machining

Precision Manufacturing, Micron-Level Tolerance Control

Using high-precision grinders, CNC machining centers and testing instruments for fine processing of key components, ensuring assembly accuracy and operational stability.

4

Component Inspection & Warehousing

Layered Inspection, Zero-Defect Warehousing

All components undergo dimensional measurement, hardness testing, and surface defect inspection before warehousing, ensuring 100% qualification rate.

5

Equipment Electromechanical Assembly

Perfect Integration of Mechanics and Electronics

Experienced assembly teams execute strict assembly standards, from mechanical component installation to electrical system wiring, with every detail precisely calibrated.

6

Complete Machine Testing

Performance Debugging, Ensuring Efficient Stable Operation

All equipment undergoes comprehensive debugging and load testing before delivery, ensuring smooth operation, precise parameters, and reliable performance.

7

Packaging & Warehousing

Safe Packaging, Global Delivery

Adopting shock-proof, moisture-proof, and rust-proof packaging standards, ensuring equipment remains safe and undamaged during transportation, delivering on time to global customers.

8

Looking for reliable forming equipment for preformed armor rods or transmission line fittings?

Our team provides fast technical support, detailed product information, and customized machine solutions for your production needs.

- info@xingangmachinery.com

- +86 15814626624

- +86 15814626624

- No. 6 Jianshe Road, Matang Town, Rudong County, Nantong, Jiangsu, China