Introduction

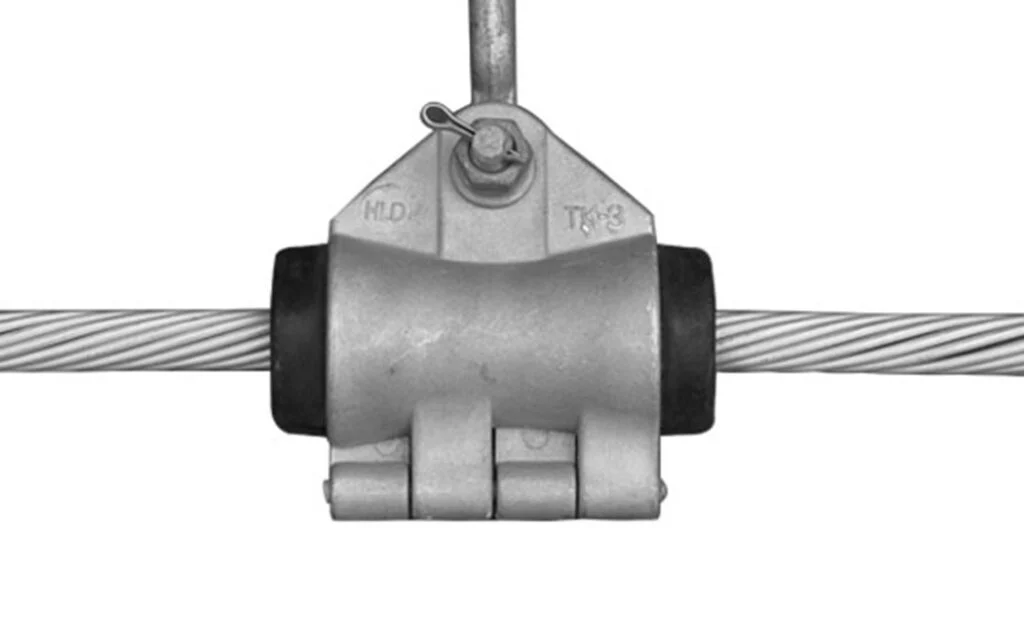

In overhead transmission line systems, suspension clamps play a vital role in supporting and protecting conductors or ground wires.

However, long-term exposure to wind load, vibration, and environmental stress can lead to clamp wear, conductor damage, or even safety hazards.

As a professional manufacturer of preformed armor rod forming equipment and power line hardware machinery, Xingang Machinery shares the key preventive and inspection measures to ensure the reliability of your suspension clamps and power lines.

Common Issues in Suspension Clamps

A typical suspension clamp consists of a hanger bolt, clevis (or body), and ship-shaped shell.

During long-term operation, the clevis pin and flat washer that secure the hanging shaft are prone to wear.

Since the washer covers the contact point, the damage is often hard to detect without removing the pin and washer for inspection.

If left unchecked, excessive wear may lead to loosening or dropping of the ground wire, causing line instability.

Key Preventive Measures

Regular Inspection

- Always remove the cotter pin and washer during maintenance to inspect wear conditions on the hanging shaft.

- Conduct thorough visual and physical checks during annual overhauls and routine maintenance cycles.

Proper Size Selection

- Choose suspension clamps according to the cross-sectional size of the ground wire or conductor.

- A mismatch may cause abrasion, deformation, or conductor slippage.

Accurate Installation Process

- During construction, follow standard procedures for wrapping aluminum tape around the contact area and tightening the wire properly.

- This reduces vibration and friction, ensuring a stable connection.

Anti-Wear and Anti-Wind Design

- In regions with strong wind or high swing amplitude, select wear-resistant alloy suspension clamps or models with anti-wind deviation components.

- These designs improve durability and reduce maintenance frequency.

Maintenance Records and Line Management

- Establish a maintenance ledger for high-risk pole sections where clamp wear is common.

- Shorten inspection intervals and implement preventive replacement schedules.

Why It Matters

In many line design standards, only the load capacity of suspension clamps is specified, while wear resistance and vibration performance are often overlooked.

Proper clamp selection and maintenance can prevent power outages, reduce repair costs, and extend conductor service life.

That’s why Xingang Machinery emphasizes both manufacturing quality and maintenance awareness — from equipment precision to the long-term reliability of every clamp installed in the field.

About Xingang Machinery

Xingang Machinery specializes in the production of Preformed Armor Rod Forming Machines, Automatic Stranding Equipment, and Overhead Line Hardware Forming Systems.

Our machines deliver:

- High precision forming with PLC and electronic pressure control

- Stable performance and low maintenance

- Exported worldwide — including India, Southeast Asia, Russia, and North America

We are committed to helping power line manufacturers achieve reliable production and safer transmission networks.

Conclusion

Suspension clamp maintenance is not just a routine task — it’s a key step in protecting your entire transmission system.

By choosing the right clamp, proper installation, and regular inspection, you can effectively prevent line damage and ensure long-term safety.

Xingang Machinery — Precision Equipment for Reliable Power Line Fittings.

Contact us to learn more about automated preformed wire and clamp forming solutions.