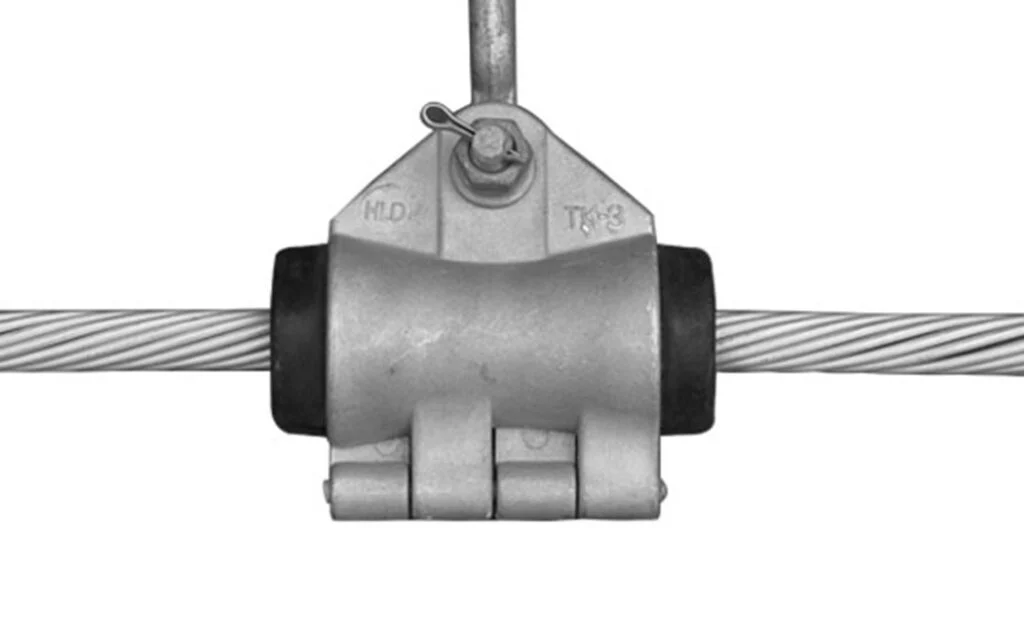

Hundreds of meters above the ground, a power line worker twists helical steel wires around a live conductor carrying tens of thousands of volts.

At first glance, it looks like a simple winding job — but in reality, this is one of the most critical and technical tasks in the transmission industry: installing preformed armor rods.

These seemingly ordinary metal rods are essential components of overhead line fittings. They provide strength, stability, and protection for high-voltage conductors facing wind, vibration, and environmental stress.

Behind their effectiveness lies not only the worker’s skill but also advanced forming technology that ensures precision and safety.

What Are Preformed Armor Rods?

Preformed armor rods — also known as preformed line accessories — are helical metal rods pre-shaped to wrap around power conductors. They’re made from aluminum alloy, galvanized steel, or aluminum clad steel, designed to fit perfectly onto the conductor surface.

Their main purposes include:

- Vibration protection: Reducing fatigue caused by aeolian vibration

- Corrosion resistance: Preventing oxidation and surface wear

- Reinforcement: Repairing or strengthening damaged conductors

- Conductor stability: Distributing mechanical stress evenly

Common variants include vibration protection rods, anti-corrosion armor rods, conductor repair rods, aluminum clad armor rods, and galvanized steel armor rods — all essential in transmission line hardware, ADSS cable accessories, and OPGW fittings.

A Skilled Job at Great Heights

Installing armor rods is far more complex than just “wrapping wires.”

Every twist must be carefully controlled. Too much force can damage the conductor; too little, and the rods won’t grip firmly.

That’s why skilled linemen must master a delicate balance — applying just enough torque to allow the metal to “flow” naturally around the conductor.

Each movement must be synchronized, letting the helical rods close tightly and evenly along the conductor’s length.

It’s a craft that combines precision, experience, and courage — performed often hundreds of meters above the ground in extreme conditions.

From Manual Skill to Automated Precision

In the past, preformed armor rods were shaped manually — a process that relied on human accuracy and experience.

Today, manufacturers have transitioned to automated preformed wire forming machines, achieving far higher efficiency and consistency.

As a professional preformed armor rods machine manufacturer, Xingang Machinery delivers cutting-edge forming solutions for the global power fittings industry.

Our equipment ensures:

- ±1° forming precision for consistent helical pitch

- Touch-screen pneumatic pressure control for real-time adjustment

- High-speed forming — up to one rod per second

- Stable wire feeding and tension systems for continuous operation

- Modular forming molds adaptable to multiple conductor types

From overhead line fittings to OPGW and ADSS cable accessories, our machines help manufacturers achieve industrial-scale production with stable quality and reduced labor costs.

The Silent Guardian of Power Lines

To the untrained eye, preformed armor rods may look like simple spirals.

But in reality, they are the silent guardians of every transmission network — absorbing vibration, preventing fatigue, and extending conductor lifespan.

They keep thousands of kilometers of power lines safe, stable, and reliable, even in harsh weather.

Behind these rods stand manufacturers like Xingang Machinery, who empower the global energy industry with automation, innovation, and precision engineering.

With our preformed line forming machines, manufacturers can produce armor rods that meet the strictest international standards — ensuring long-term reliability for every transmission project.

Conclusion

Every twist of an armor rod tells a story — of human skill, mechanical precision, and technological evolution.

From manual craftsmanship to intelligent automation, preformed armor rods represent the fusion of engineering excellence and safety innovation.

Xingang Machinery continues to lead this transformation, providing high-speed, high-precision machines that help the world’s power hardware manufacturers strengthen their lines — and their businesses.

✨ Boost your efficiency, improve product consistency, and protect every connection with Xingang’s preformed armor rod forming machines.

???? Contact us today to learn more about our full overhead line fittings production solutions.